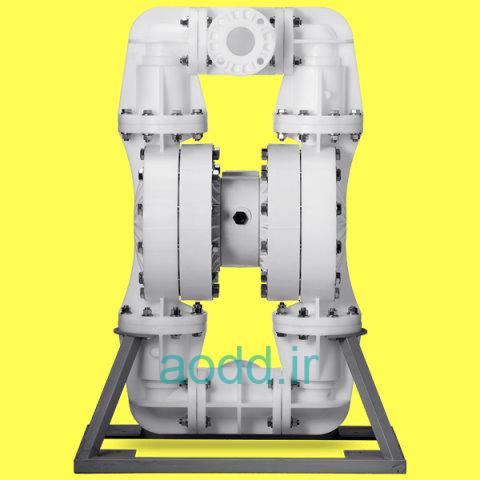

Industrial machines are designed and built to increase quality and production without much human intervention. However, in order to continue to remain active and keep the quality and output at the desired level, mechanical equipment must be well lubricated. Pneumatic diaphragm pumps are a suitable solution for transferring and distributing machine lubricating oils and are considered as an important part of an automatic lubrication system. It should be noted that manual lubrication systems can also be effective, but they often cause problems such as inaccuracy, contamination, and non-uniform lubrication of surfaces. The use of an automatic lubrication system ensures the complete injection of lubricant on the surfaces in a timely and regular manner. In the following , we describe the features of a diaphragm pump suitable for use in automatic lubrication systems and its advantages.

Advantages of oil transmission diaphragm pumps

- Reasonable price: Air diaphragm pumps have a lower cost compared to other automatic lubrication systems.

- Easy maintenance: these pumps have a low maintenance cost compared to other systems with a long life and reduced moving parts.

- Pumping thick liquids: Diaphragm pumps are designed in such a way that they are able to transfer all kinds of liquids with high viscosity.

- Use of compressed air: Due to the absence of an electric motor in pneumatic diaphragm pumps, these pumps have an easier installation compared to electric pumps, and their lifespan is higher due to the reduction of the operating temperature.

- Versatility: Diaphragm pumps have the capability of dry operation, super suction and the ability to create high pressures at the output, for this reason they are compatible with all types of lubrication and oil transfer systems.

The best diaphragm pump for lubrication systems

According to the experience of All-Flo company, choosing a diaphragm pump made of aluminum body material with a Geolast diaphragm is the best and most economical option for transporting lubricating oils. These pumps can withstand temperatures up to 82 degrees Celsius and create a maximum pressure of 8.2 bar at the outlet. Aluminum diaphragm pumps of this company are designed and manufactured in 1/2 to 3 inch sizes. If you need help in choosing the right diaphragm pumps for automatic lubrication systems, you can contact our experts in the sales department. Also, in order to make it easier to choose and get to know more about the features and technical specifications, some of the most popular models of diaphragm pumps of All-Flo company are shown in the table below.

|

Model

|

A050

|

A100

|

A150

|

A200

|

A300

|

|---|---|---|---|---|---|

|

size

|

1/2

|

1

|

1.1/2

|

2

|

3

|

|

body

|

Aluminum

|

Aluminum

|

Aluminum

|

Aluminum

|

Aluminum

|

|

Diaphragm

|

Geolast

|

Geolast

|

Geolast

|

Geolast

|

Geolast

|

|

connections

|

FNPT (FBSPT)

|

FNPT (FBSPT)

|

FNPT (FBSPT)

ANSI/DIN FLANG |

FNPT (FBSPT)

ANSI/DIN FLANG |

FNPT (FBSPT)

ANSI/DIN FLANG |

|

Maximum flow rate (lit/min)

|

56.8

|

182

|

435

|

719

|

890

|

|

Maximum pressure (bar)

|

8.2

|

8.2

|

8.2

|

8.2

|

8.2

|

|

Maximum temperature C

|

87

|

87

|

87

|

87

|

87

|

|

Solid particles (mm)

|

6.4

|

6.4

|

6.4

|

6.4

|

11

|