Processing of metals such as steel is one of the oldest and most consumed industrial markets. There is a need to pump liquids in all stages, including the processing of raw metals to additional applications such as the production of metal coatings. The use of diaphragm pumps is recommended for steel and steel industries due to maximum compatibility, reliability and easy maintenance in transferring all kinds of materials. Some of the applications of diaphragm pumps in these industries include making metal chips, electroplating, conveying waste, settled solids, acids and caustic sodas. The correct selection of these pumps can greatly reduce the costs caused by stopping the production lines and the need for maintenance. In the following, we explain how to choose the right diaphragm pump for the steel industry.

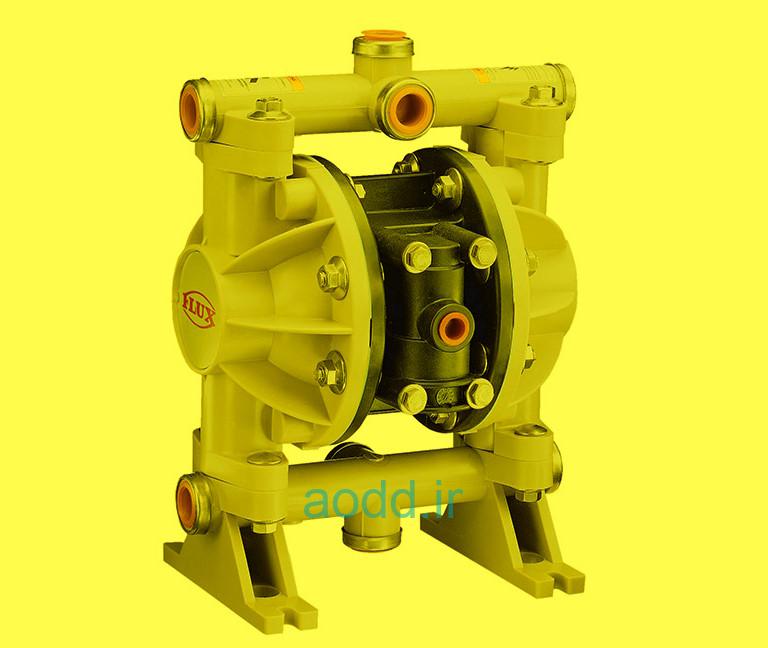

Choosing a diaphragm pump for metal industries

Diaphragm pumps of steel and steel industries must have maximum resistance against the corrosion of chemicals and metal particles. The material of these pumps can be selected according to the type of material and the temperature, corrosiveness and abrasiveness of the fluid. All-Flo recommends the use of diaphragm pumps with a polypropylene body and a Santoprene diaphragm. If you need help choosing the right pump, you can use the table below or contact our experts in the sales department.

|

Model

|

A025

|

C038

|

A050

|

A075

|

A100

|

C150

|

A200

|

|---|---|---|---|---|---|---|---|

|

size

|

1/4

|

3/8

|

1/2

|

3/4

|

1

|

1.1/2

|

2

|

|

body

|

PP

|

PP

|

PP

|

PP

|

PP

|

PP

|

PP

|

|

Diaphragm

|

Santoprene

Elastomers |

Santoprene

Elastomers |

Santoprene

Elastomers |

Santoprene

Elastomers |

Santoprene

Elastomers |

Santoprene

Elastomers |

Santoprene

Elastomers |

|

connections

|

FNPT (FBSPT)

|

FNPT (FBSPT)

|

FNPT (FBSPT)

|

FNPT (FBSPT)

|

FNPT (FBSPT)

ANSI/DIN FLANG |

ANSI/DIN FLANGE

|

ANSI/DIN FLANGE

|

|

Maximum flow rate (lit/min)

|

21.6

|

34

|

64.6

|

64.4

|

115.8

|

492

|

681

|

|

Maximum pressure (bar)

|

8.2

|

8.2

|

8.2

|

8.2

|

8.2

|

8.2

|

8.2

|

|

Maximum temperature C

|

62

|

62

|

62

|

62

|

62

|

62

|

62

|

|

Solid particles (mm)

|

1.6

|

1.6

|

3.2

|

3.2

|

6.4

|

6.4

|

6.4

|

Diaphragm pump application in steel industries

- Filter press: removing metal particles from water so that it can be recycled and reused.

- Sewage tanks: removal of waste in metal processing such as sludge treatment and removal of solid materials without damaging the diaphragms

- Transfer of chemicals: pumping corrosive substances such as caustic soda and slurry

- Production process: pumping and circulation of chemicals in production processes such as electroplating and polishing the surface of metals

- Washing: removing oil and degreasing