Download Graco Husky 2150 diaphragm pump manual

- Graco-Husky 2150 Technical Specifications

- graco husky 2150 Plastic Instructions Parts List

- graco husky 2150 Metal Instructions Parts List

Technical specifications of Graco Husky 2150 diaphragm pump

Inlet and outlet diameter: 2 inches

Air inlet diameter: 1/2 inch

Maximum output flow rate: 568 liters per minute

Maximum outlet pressure: 8.4 bar

Maximum suction depth: 6.1 meters

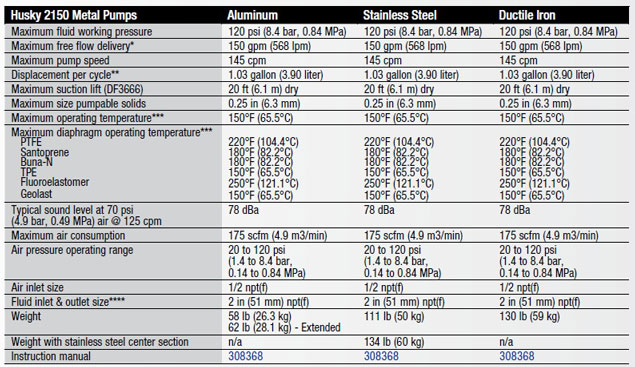

Graco Husky 2150 diaphragm pump specification table

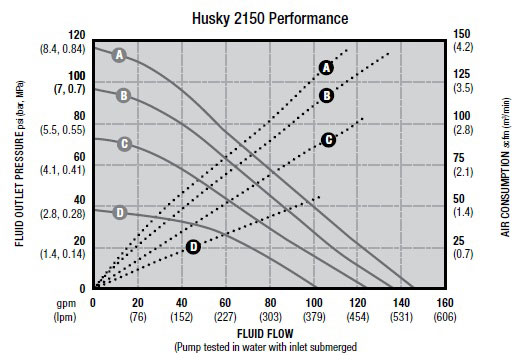

Graco Husky 2150 diaphragm pump characteristic curve

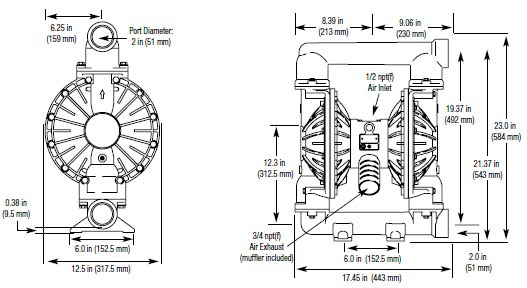

Structural diagram of Graco Husky 2150 diaphragm pump

INTRODUCTION OF GRACO DIAPHRAGM PUMP HUSKY 2150 MODEL

Diaphragm pump Graco Model 2150 Husky is a powerful turbine pump of this company, which can move and pump up to 568 liters per minute with a maximum working pressure of 8.4 bar. This powerful pump has a 2-inch material inlet and outlet and can transfer all kinds of fluids such as alcohols, bases, acids, edible and industrial oils, etc. Another advantage of this American Graco diaphragm pump is the maximum suction depth of 6.3 meters, and the user can use this device in various industries such as petrochemicals, factories, laboratories, etc. Also, this device has the ability to easily pump liquids with particles up to 2.4 mm without settling inside the device. Some fluids may destroy this device due to their corrosive properties, that’s why this model of diaphragm pump is available in PP (polypropylene), Alu (aluminum) and SST (stainless steel) materials. Each of these pumps is unique for transferring fluids and special materials.

- Compressed air drive.

- The maximum flow rate is 568 liters per minute and the maximum head is 84 meters

- Recently, the new Husky2200 model series has replaced this series

- It is one of the most used and old Graco models

- In metal body models, the inlet and outlet size of the pump is “2” and it is threaded.

- In plastic body models, the pump inlet and outlet size is “2” and flanged.

- The material of the pump shell can be aluminum or stainless steel 316. (Metal body)

- The material of the pump shell can be polypropylene, Stal or Kaynar. (plastic body)

- For the material of the diaphragm, you can choose Hytrel, Centoprene, natural rubber or Teflon.

- The material of the bullet can be steel, Teflon, stainless steel.

- The seating material of the bullet (seat) can be hytral or stainless steel.

- The air part of the pump is made of aluminum with epoxy coating.

- If needed, it is possible to order the middle shell with 316 stainless steel material.

- This model has the ability to pass solid particles with a diameter of more than 6.5 mm.

Technical specifications of Graco Husky 2150 diaphragm pump

Husky 2150 plastic diaphragm pump

| Diaphragm pump Graco Husky 2150 PP body | Diaphragm pump Graco Husky 2150 PVDF body |

| Husky 2150 plastic diaphragm pump | Polypropylene/kynar | |

| Maximum working pressure | 8.4 bar (0.84MPa – 120psi) | |

| Maximum flow rate | 568 liters per minute (150 gpm) | |

| Maximum pump speed | 145cpm | |

| Movement in each cycle | 3.90 liters (1.03 gallons) | |

| Maximum suction depth | 5.48 m (18 ft) dry | |

| Maximum size of solid particles | 6.3 mm (0.19 in) | |

| Maximum working temperature | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| The maximum operating temperature of the diaphragm | PTFE | 104.4 degrees Celsius (220 degrees Fahrenheit) |

| Santoprene | 82.2 degrees Celsius (180 degrees Fahrenheit) | |

| Hi | 82.2 degrees Celsius (180 degrees Fahrenheit) | |

| TPE | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| Fluoroelastomer | 121.1 °C (250 °F) | |

| Geolast | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| Typical sound level at 4.9 bar (0.49MPa – 70psi) air pressure at 125 cpm | 78 Dec. Bill | |

| Maximum air consumption | 4.9 cubic meters per minute (175Scfm) | |

| Air consumption at 4.9 bar (0.49Mpa – 70psi) | 1.7 cubic meters per minute (60Scfm) | |

| Working air pressure range | 1.4 to 8.4 bar (0.14 to 0.84 MPa – 20 to 120 psi) | |

| Air inlet size | 1/2 (npt(f | |

| Fluid inlet and outlet size | 51 mm (2″) ANSI-Flange | |

The weight of the Husky 2150 metal diaphragm pump is different with different body materials:

- Polypropylene (PP) body: 22 kg (49 lb)

- Body (PVDF) Kaynar: 30.8 kg (68 lb)

Technical specifications of Graco Husky diaphragm pump 2150 series

One of the Graco Husky brand pumps is a diaphragm pump that is produced in several different series. Diaphragm pump Graco 2150 series is one of its types, which will be explained below.

In this model of Graco Husky diaphragm pump, polypropylene, stainless steel, aluminum, conductive iron and PVDF are used to make the body and Santoprene, TPE, BUNA and PTFE are used for its diaphragm. This series of pumps are suitable for temperatures up to 65.5 degrees Celsius. The maximum size of suspended solid particles in them can be up to 6.3 mm. Its maximum pressure and flow are 8.4 bar and 34 cubic meters per hour, respectively.

Among the most important advantages of the Graco Husky diaphragm pump, the following can be mentioned:

Working with wind power

Available in several types

Specifications

Body Material

Dubai

Maximum working pressure

Fluid inlet pipe diameter

The diameter of the fluid outlet pipe

The maximum size of solid particles

The maximum operating temperature of the diaphragm

Maximum pump speed

Maximum suction depth

Air inlet size

Displacement per cycle

Weight

Warranty conditions

Application of Graco 2150 series diaphragm pump

Examples of the applications of this type of pump can be summarized in the following cases:

- Transfer of all kinds of materials in the chemical industry

- Food industry

- Petrochemical Industries

Graco Husky 2150 Plastic Diaphragm Pump Performance Chart

Dimensions of Graco Husky 2150 plastic diaphragm pump

Husky 2150 metal diaphragm pump

| Diaphragm pump Graco Husky 2150 AL body | Diaphragm pump Graco Husky 2150 stainless steel body |

| Diaphragm pump Graco Husky 2150 iron body | |

| Husky 2150 metal diaphragm pump | Aluminum/stainless steel/iron | |

| Maximum working pressure | 8.4 bar (0.84MPa – 120psi) | |

| Maximum flow rate | 568 liters per minute (150 gpm) | |

| Maximum pump speed | 145cpm | |

| Displacement per cycle | 3.90 liters (1.03 gallons) | |

| Maximum suction depth | 6.1 m (18 ft) dry | |

| Maximum size of solid particles | 6.3 mm (0.19 in) | |

| Maximum working temperature | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| The maximum operating temperature of the diaphragm | PTFE | 104.4 degrees Celsius (220 degrees Fahrenheit) |

| Santoprene | 82.2 degrees Celsius (180 degrees Fahrenheit) | |

| Hi | 82.2 degrees Celsius (180 degrees Fahrenheit) | |

| TPE | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| Fluoroelastomer | 121.1 °C (250 °F) | |

| Geolast | 65.5 degrees Celsius (150 degrees Fahrenheit) | |

| Typical sound level at 4.9 bar (0.49MPa – 70psi) air pressure at 125 cpm | 78 Dec. Bill | |

| Maximum air consumption | 4.9 cubic meters per minute (175Scfm) | |

| Working air pressure range | 1.4 to 8.4 bar (0.14 to 0.84 MPa – 20 to 120 psi) | |

| Air inlet size | 1/2 (npt(f | |

| Fluid inlet and outlet size | 51 mm (2″) npt(f) or bspt(f) | |

The weight of the Husky 2150 metal diaphragm pump is different with different body materials:

- Aluminum body: 26.3 kg (58 lb)

- Stainless steel body: 50 kg (111 lb)

- Iron body: 59 kg (130 lb)

General information

Technical Specifications

Review

- American Graco diaphragm pump can be considered one of the best diaphragm pump brands in Iran.

- This pump is used for various industries that require a very high performance pneumatic pump.

- The performance of this pump is displayed on the diaphragm pump page. This pump can well pump fluids with small solid particles and create a uniform flow.

- For a better choice, you can contact the sales experts of industrial goods.

- Husky pump model 2150 is similar to 1590 in terms of construction and body design. This pump works in difficult conditions without the need for lubrication.

- Husky 2150 pump is produced in SST, PP, KY, CS, AL materials.

Graco Husky 2150 diaphragm pump price list

Model No. Description

*DF3______ Aluminum Pumps

*DG3______ Aluminum Pumps, Remote

*DFH______ Aluminum Extended Pump

Diaphragm pump HUSKY Graco 2150 Graco Husky

*DGH______ Aluminum Extended Pump, Remote

*DF4______ Stainless Steel Pumps

*DG4______ Stainless Steel Pumps, Remote

*DF6______ Ductile Iron Pumps

*DG6______ Ductile Iron Pumps, Remote

*DFC______ Aluminum BSPT Pumps

*DGC______ Aluminum BSPT Pumps, Remote

*DFD______ Stainless Steel BSPT Pumps

*DGD______ Stainless Steel BSPT Pumps, Remote

*DFF______ Ductile Iron BSPT Pumps

*DGF______ Ductile Iron BSPT Pumps, Remote

*DFG______ Aluminum BSPT Extended Pump

*DGG______ Aluminum BSPT Extended Pump, Remote

*DV4______ Stainless Steel Plus Pumps

*DVD______ Stainless Steel BSPT Plus Pumps

232503 Private–Label Aluminum 2150 Pump (See page 22.)

24B782 Aluminum Pump with overmolded diaphragms

24B783 Stainless Steel Plus Pump with overmolded diaphragms

24B801 Stainless Steel Pump with overmolded diaphragms

24G413 Aluminum BSPT with overmolded diaphragms

24J360 Aluminum Pump with overmolded diaphragms

Changing the Orientation of the Fluid Inlet and Outlet Ports The pump is shipped with the fluid inlet (R) and outlet (S) ports facing the same direction. See Fig. 3. To

change the orientation of the inlet and/or outlet port: 1. Remove the screws (106) holding the inlet (102)

and/or outlet (103) manifold to the covers (101). 2. Reverse the manifold and reattach. Install the

screws and torque to 120 to 150 in-lb (14 to 17 Nm). on aluminum pumps. Torque to 190–220

in–lb (22–25 Nm) on ductile iron and stainless steel pumps. See Torque Sequence, page 29.

03940B Fig. 3

1 Apply medium-strength (blue) Loctite or equivalent to the threads. Torque to 120 to 150 in-lb

(14 to 17 Nm) on Aluminum pumps. Torque to 190–220 in–lb (22–25 Nm) on ductile iron and stainless steel pumps. See Torque Sequence, page 29.

KEY N 1/2 npt(f) air inlet port P Muffler. Air exhaustport is 3/4 npt(f). R 2 npt(f) fluidinlet portS 2 npt(f) fluid

outlet port101 Covers HUSKY Graco 2150 diaphragm pump

102 Fluid inlet manifold 103 Fluid outlet manifold 106 Manifold and cover screws 112 Cover screws (top and bottom) HUSKY Graco 2150 diaphragm pump

Aluminum Model Shown103102 1011061122 Apply medium-strength (blue) Loctite or equivalent to the threads. Torque to 190 to 220 in-lb(22 to 25 Nm).106 2

2Fluid Pressure Relief Valve

Some systems may require installation of a pressure relief valve at the pump outlet to prevent overpressurization and rupture of the pump or

hose. See Fig. 4.

Thermal expansion of fluid in the outlet line can cause overpressurization. This can occur when using long fluid lines exposed to sunlight or ambient heat, or when pumping from a cool to a warm

area (for example, from an underground tank). Overpressurization can also occur if the Husky pump is being used to feed fluid to a piston pump, and the intake valve of the piston pump does not close, causing fluid to back up in the outlet line.

CAUTION

Fig. 412 Connect fluid inlet line here.KEY R 2 npt(f) fluid inlet port S 2 npt(f) fluid outlet port V Pressure relief valve Part No. 112119 (stainless steel)RS Connect fluid outlet line here.

HUSKY Graco 2150 diaphragm pump applications

- Due to the flow rate and high pressure, HUSKY Graco 2150 Diaphragm Pump is one of the best choices for the wastewater treatment industry.

- It is one of the best options for filter press pumps in the water treatment industry.

- Working 24 hours a day without stopping and not needing many control equipments that are usual for electric pumps is one of the advantages of this pump.

- In drilling industries and oil rigs, HUSKY Graco 2150 Diaphragm pump is suitable for transferring water and mud mixture as well as bentonite.

- In tile and ceramic industries, HUSKY Graco 2150 diaphragm pump is used to transfer glaze and grout.

- Models with stainless steel body are used in paper and cardboard factories to transfer starch glue.

The strengths of HUSKY Graco 2150 diaphragm pump

- Flow rate 568 liters per minute

- Ability to transfer solid particles along with fluid up to 6.8 mm in size.

- HUSKY Graco 2150 Diaphragm pump is reliable and has minimal wearing parts.

- Continuous operation without the need for service and maintenance.

- Made in America.

Disadvantages of HUSKY Graco 2150 diaphragm pump

- Heavy weight and volume

- High air consumption

Air valve repair service

Tools required: torque wrench

Torx (T20) or 7mm (32/9″) socket screwdriver

Narrow tail wrench selection O ring

lithium base grease

Note: Air valve repair kit 236273

(aluminum center housing) and 255061 (stainless steel center housing) are available. See page 24. The parts in

the kit are marked with a symbol, for example (4).

Use all the parts in the kit for best results.

deassembleing

1. Follow the pressure relief procedure warning on page 10

2. With a Torx (T20) or 7 mm (9/32 inch) screwdriver

Remove the socket wrench, six screws (3), air

valve cover (2) and washer (4). See Figure 6.

3. Move the valve carriage (5) to the middle position

and pull it out of the cavity. Remove valve

block (7) and o-ring (6) from carriage. Using a pair of

needle nose pliers, pull the pilot block (18) straight

up and out of the hole see Figure 7.

4. Pull out the two driving pistons (11) from the bearing (12). u-cup packs (10) from

Pistons Pull the pilot pins (16) out of

the bearing (15). Remove the circlips (17) from the

pilot pins, see Figure 8.

5. Check valve plate (8) in place. If damaged,

use a Torx screwdriver (T20) or a 7 mm (9/32 inch)

socket wrench to remove the three screws (3).

Remove the valve plate (8) and the aluminum plate

Center housing models only, remove seal (9).

See figure 9 HUSKY Graco 2150 diaphragm pump.

6. Check the bearings (12, 15) in place. See Figure 8.

The bearings are tapered and in case of failure, must

be removed from the outside, this requires the separation of the fluid part. See page 20.

7. Clean all parts of HUSKY Graco 2150 Diaphragm Pump and check for wear and damage.

Replace if needed.

Reassemble as described above

Page 14

03944

Torque to 50 to 60 in. (5.6 to 6.8 Nm).

Figure 6342203945185

Figure 712

See details on the right.

Grace.

3 Grease the face below.1765233

11

1614 308368

Service

03946

Figure 8

17 1611

101215

1

2 Insert the narrow end first,

grease.

3 Install with the lips facing the narrow end of the piston (11).

42 1

342

Enter the HUSKY Graco 2150 Wide End Diaphragm Pump

039471289

3. The round side must face down (aluminum center only housing models)

Tighten the screws until they come down

Outside the housing Figure 9 12

Reassembly

1. If you have removed the bearings (12, 15), install new

ones as described on page 20.

Fluid section

2. In aluminum housing models, install the device

valve plate seal (9) Place it in the bottom groove

from the round side valve hole of the HUSKY Graco 2150 Diaphragm Pump, the seal

must be facing into the groove. See Figure 9.

3. Install the valve plate (8) in the cavity. In aluminum housing models, the plate is reversible,

so each side can face up. Install the three screws

(3), using a Torx (T20) screwdriver or a 7 mm (32/9 in)

socket wrench. Tighten until the screws are down

on the housing, see Figure 9.

4. Install a washer (17) on each pilot pin (16). Grease the pins and rings of the ring. Insert the pins into

the bearing (15), narrow end first. See Figure 8.

5. Install a u-cup pack (10) on each actuator

piston (11), so the lip of the pack faces the

narrow end of the pistons (see Figure 8).

6. Lubricate the u-cup packing (10) of HUSKY Graco 2150 Graco Husky Diaphragm Pump and Actuator

Piston (11). Drive pistons into

bearings (12), wide end first. Release the narrow

ends of the pistons are exposed see Figure 8.

7. Grease the lower part of the pilot block (18) and

Install so that its tabs are fixed to the grooves on

the ends of the HUSKY Graco 2150 diaphragm pump pilot pins (16). See Figure 7.

8. Grease the o-ring (6) and install

it in the valve block (7) Press the block on the valve carriage

(5) Grease the underside of the valve block. See Figure 7

9. Install the valve cover (5) until its tabs slide in

Grooves in the narrow end of the actuator pistons

(11) see Figure 7.

10. Align the valve gasket (4) and the cover (2) with

the six holes in the central housing (1). Safe with six

Screw (3), using Torx screwdriver (T20) or 7

32.9 mm socket wrench.

Torque up to 50 to 60 in-lbs (5.6 to 6.8 Nm). See Figure 6.