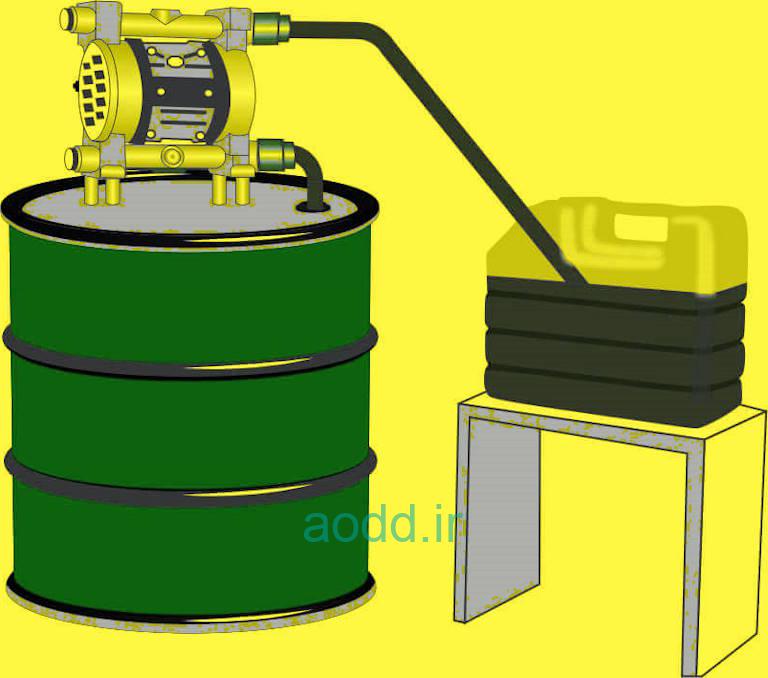

Diaphragm pumps are designed and manufactured in air (pneumatic) and electric models. Air models are mainly used to transfer liquids and electric models are used for precise injection of materials. These pumps are also known as multipurpose pumps due to their unique features and design. One of the special features of diaphragm pumps is the ability to suck liquid from negative depths without the need for aeration, and for this reason, they are widely used in emptying barrels and tanks. These pumps are able to transfer a wide range of materials such as thick, corrosive, aggressive (abrasive), toxic, flammable, etc. liquids. In this article, we intend to guide you in choosing the right diaphragm pump. The correct selection of these pumps, in addition to maintaining safety, can greatly reduce maintenance and production costs in industrial and process units.

Important points in choosing a diaphragm pump

Type of fluid: The most important factor that must be considered is the type, composition and nature of the fluid to prevent corrosion and wear of the parts in contact with it. For example, chemicals and acids can cause corrosion, as well as slurry or liquids containing abrasive solids. In the following, we explain the nature of the fluid more fully.

- Corrosive fluids: fluids such as sulfuric acid, hydrochloric acid, caustic soda (sodium hydroxide), etc. can be very corrosive and damage different parts of diaphragm pumps. For example, for transferring sulfuric acid, a pump with a PVDF body and a diaphragm made of Teflon (PTFE) or Santoprene is recommended.

- Abrasive liquids (slurry): Liquids such as slurry, glaze, paint, ink, etc. that contain solid particles can be highly abrasive and damage different parts of diaphragm pumps. For example, to transfer colors, we can use a pump with a steel or aluminum body with a Teflon (PTFE) diaphragm. It is also recommended to use diaphragm pumps with PP body and Santoprene diaphragm to transfer slurries and slurries.

Chemical compatibility of materials with pump parts

One of the important things in buying diaphragm pumps is the chemical compatibility of materials with pump parts. For example, some acids such as hydrochloric acid cause corrosion in metal parts, or petroleum derivatives (hydrocarbons) dissolve rubber parts. The parts in contact with liquid in diaphragm pumps include the body, balls, seats, O-rings and diaphragms. The following tables show the permitted materials in the structure of diaphragm pumps for the transfer of various chemicals, acids, solvents, etc. To check a specific material, you can easily enter its name in the search bar so that the results will be shown to you.

Degree of resistance

A: Good

B: Average

C: Poor

D: Unsuitable

–: Not tested

- Body Material

- Diaphragm type

- Toxic liquids: Lead, mercury, aniline and arsenic compounds are among the toxic substances that are harmful to human health and even fatal. The use of diaphragm pumps is recommended due to the lack of seals in their movement. Some diaphragm pumps have a diaphragm leakage detection system that is ideal for transporting toxic liquids.

- Flammable liquids: Varnish, acetone, alcohol, thinner, gasoline, oil, etc. are flammable liquids. The use of AODD pumps is very suitable for transferring these liquids. Since the driving force of diaphragm pumps is generally compressed air, these pumps are inherently anti-friction. But for more certainty in the transfer of flammable and explosive materials, it is recommended to use diaphragm pumps with ATEX certification.

- Stress-sensitive liquids: substances such as curd, ketchup, paint and emulsions may lose their properties if exposed to shear stress. Some of these materials may become thinner or thicker even in the face of shear stress. Since the operating speed in diaphragm pumps is adjustable, their use is recommended for conveying pressure-sensitive liquids. It is better to reduce the speed as much as possible in the transfer of such materials.

- Low vapor pressure: Liquids such as diesel, oil and hydrocarbons have a low vapor pressure, so it should be noted that the pump works at a low speed and the suction depth is not high. Due to the speed adjustment in diaphragm pumps, these pumps are a suitable option for transferring diesel and hydrocarbons.

Viscosity: Viscosity is the resistance of a liquid to flow, and in other words, the degree of concentration or stickiness of the fluid. AODD pumps are a good option for transferring thick liquids. Liquid concentration is very important in choosing the size of diaphragm pumps. For example, to transfer materials with a viscosity higher than 5000 centipoise, it is recommended to use AODD pumps with a minimum size of 1.1/2 inches. Also, viscous liquids require a higher output pressure for transportation due to more frictional losses in pipelines. Performance curves of diaphragm pumps are drawn based on water properties, and manufacturing companies provide a viscosity correction factor appropriate to pump size. Pump performance curves for thick liquids are plotted based on the viscosity correction factor. For a better understanding, the viscosity of some materials in centipoise is presented in the table below.

|

Type of material

|

In English

|

Dynamic viscosity cP (mPa.s)

|

|---|---|---|

|

Water

|

Water

|

1

|

|

Lion

|

Milk

|

3

|

|

SAE 10 engine oil

|

Motor Oil SAE 10

|

85~140

|

|

SAE 20 engine oil

|

Motor Oil SAE 20

|

140~420

|

|

SAE 30 engine oil

|

Motor Oil SAE 30

|

420~650

|

|

SAE 40 engine oil

|

Motor Oil SAE 40

|

650~900

|

|

Castor oil

|

Castor Oil

|

1.000

|

|

corn syrup

|

Corn Syrup

|

5.000

|

|

honey

|

Honey

|

10,000

|

|

Chocolate

|

Chocolate

|

25,000

|

|

Ketchup

|

Ketchup

|

50,000

|

|

mustard

|

Mustard

|

70,000

|

|

Sour cream

|

Sour Cream

|

100,000

|

|

peanut butter

|

Peanut butter

|

250,000

|

Pressure: Determining the inlet (suction) and outlet (flow) pressure helps to choose the right diaphragm pump.

- Inlet pressure: Diaphragm pumps are self-priming and in addition to pumping turbulent flow, they also have the ability to suction from negative depths. If the input pressure in AODD pumps exceeds the permissible limit, it affects the opening and closing of the valves and causes malfunction of the pump.

- Output pressure: It is called output pressure in head diaphragm pumps. In these pumps, the pressure of the inlet air and the outlet pressure of the liquid have a ratio of 1 to 1. Of course, in some high pressure pumps, this ratio is 1 to 2 and the output pressure of the pump can increase up to 16 bar.

Flow rate: flow rate is the amount of liquid outflow per unit of time. This parameter is directly related to determining the size of the inlet and outlet of diaphragm pumps. The flow rate in these pumps is usually shown in lit/min, gpm or m3/hr units.

Temperature: AODD pump components have temperature limitations. Operating temperature and environmental conditions are influential in choosing the right diaphragm pumps. For example, the neoprene diaphragm is not suitable for temperatures above 100 degrees Celsius. The table below shows the permissible temperature range of common materials used in diaphragm pumps.

|

Material of pump parts

|

In English

|

Allowed temperature range (Celsius)

|

|---|---|---|

|

Polypropylene

|

Polypropylene

|

0~79

|

|

Polyvinylidene fluoride

|

PVDF

|

-12 ~ 107

|

|

stainless steel

|

Stainless steel

|

-28 ~ 104 *

|

|

aluminium

|

Aluminium

|

-28 ~ 104 *

|

|

Cast iron

|

Cast Iron

|

-28 ~ 104 *

|

|

Natural rubber (nitrile)

|

Buna-N (NBR)

|

-12 ~ 65

|

|

synthetic rubber

|

Neoprene

|

-17 ~ 93

|

|

EPDM

|

EPDM

|

-51 ~ 137

|

|

Polyurethane

|

Polyurethane

|

-12 ~ 65

|

|

centoprene

|

Santoprene

|

-28 ~ 104

|

|

Teflon

|

PTFE

|

4.4 ~ 104

|

* The temperature listed is without considering the rubber parts used in the pumps.

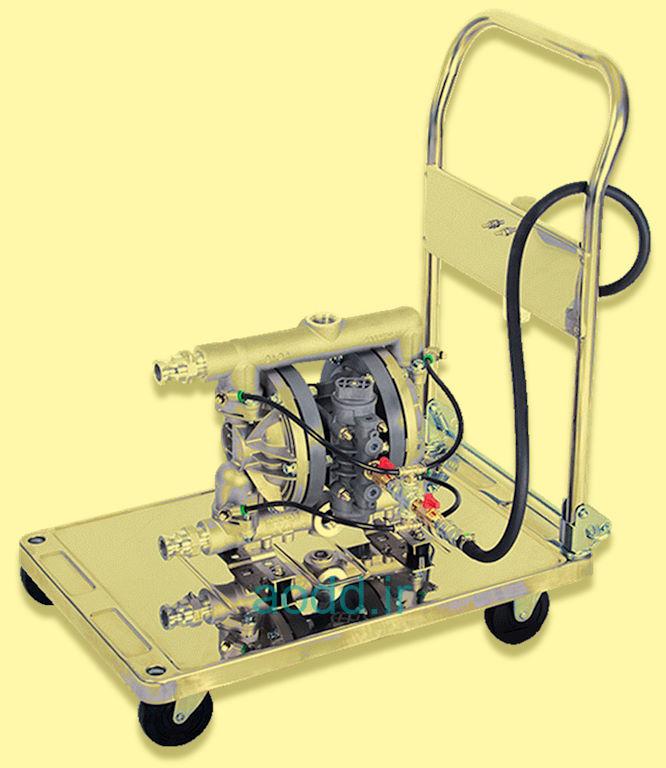

Application: AODD pumps can be used for permanent work as well as intermittent work. These pumps are mainly used for emptying and transferring liquids. The ability to be fixed or portable on wheels is one of the advantages of diaphragm pumps. It is enough to have access to compressed air at the point of consumption.

Compressed air: As the name of Air Operated Double Diaphragm pumps indicates, the power required for the operation of these pumps is provided by compressed air. So before buying a diaphragm pump , make sure you have access to compressed air. It should be noted that some of these pumps can work with natural gas or nitrogen.