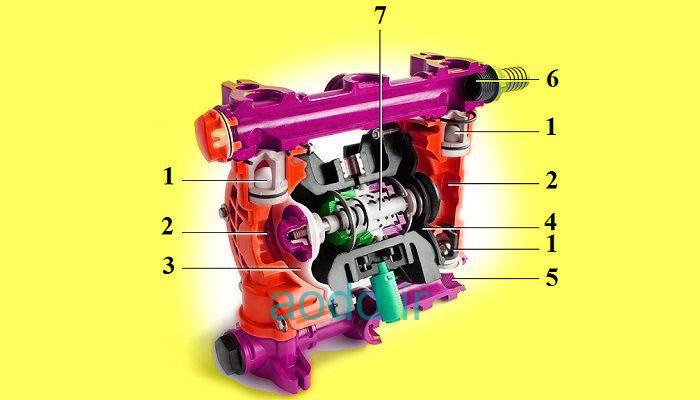

In this article, we intend to examine how to install pneumatic diaphragm pumps according to standard instructions. As you know, the driver of these pumps is compressed air supplied by the compressor. The compressed air line must have a main valve with a pressure regulator. In cases where clean air free of oil or moisture is needed, it is recommended to filter the air entering the pump. In order to monitor and control the liquid flow, a pressure gauge can be used in the outlet of diaphragm pumps. In systems where the outlet path is closed, a drain line with a pressure relief valve should be designed. The use of shock absorbers in the inlet and outlet of the pump, as well as the installation of pulsation dampers in the liquid outlet can reduce up to 98% of the vibrations caused by the back and forth of the diaphragm. The connections required for installing diaphragm pumps are shown in the picture below.

Important points in installing diaphragm pumps

During the installation of diaphragm pumps, people who are not familiar with the pump and its installations often make small mistakes that lead to many financial losses. In the following, we explain some points that can prevent these damages:

- Diaphragm pumps must be installed on a solid surface. The base of these pumps is easily screwed on the plates.

- The diameter of the suction pipe (pump inlet) should not be reduced in any way.

- The diameter of the suction pipe should not be smaller than the diameter of the inlet port in diaphragm pumps.

- The length of the suction pipe should be as short as possible and not more than 5 meters for the correct operation of the pump.

- The diameter of the discharge pipe (pump outlet) can be reduced to a reasonable extent according to the design requirements.

- In the pump inlet air path, it is recommended to use a pressure regulator with an air filter.

- The air pressure should be set to 2 bar at first start-up, especially if the diaphragms are made of Teflon.

- In order to increase the life of the pump and reduce the maintenance costs, it is recommended to adjust the speed of the diaphragms in such a way that the work cycle is 60 to 70 per minute.